Since the onset of the pandemic, the economy has been declining due to measures put in place to contain the pandemic. In 2022, there are numerous signs that there’ll be economic growth and development because there will be no disruptions in the manufacturing industry. The manufacturing industry is recovering from various negative impacts of the COVID-19 pandemic, such as:

- Supply chain disruptions

- The labor shortage

- Worker’s roles and responsibilities with the rise of automation

- The skill gap

- Attracting and retaining new employees

There are some strategies put in place to shape the manufacturing industry in 2022. This shows that companies are ready to prepare for the future in terms of increasing the rate of productivity. Based on research, technology plays a significant role in improving the overall growth of the economy.

The current manufacturing trends incorporate high-tech innovations that enhance the sustainability of the production processes. The main objective of manufacturing companies is to optimize profit and reduce the overall production cost.

Therefore, in the aftermath of the pandemic, firms will look for ways to improve productivity with minimal manpower. This is the main reason why scale-ups and start-ups are developing immersive technology gadgets, smart sensors, and wearables that reduce manpower. Below are 5 manufacturing trends to watch in 2022 and beyond.

Table of Contents

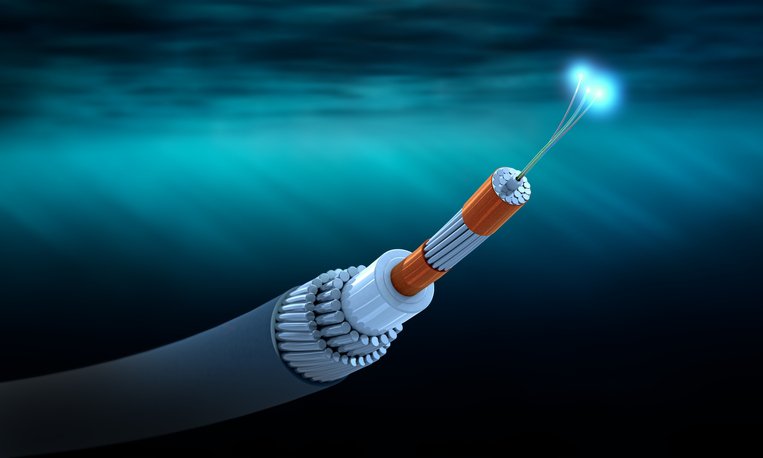

1. Connected Services

Technology improvement plays a significant role in enhancing business operations. In addition, technology improves the quality of products. Connected services are a great deal in 2022, especially internet-based products, such as hand tools, healthcare devices, turbines, machinery, etc.

Also, JD Edwards Managed Services are important in both strategic guidance and functional support. In the future, most firms will be opting for pay-per-output and pay-per-use. This means that clients and customers won’t be paying for the actual product but for the general benefit of the product. Below are some of the key opportunities for the connected services:

- Predictive maintenance

- Vehicle telematics

- Smart home automation and solutions

- Remote control over machines and equipment

Connected services create a great experience for clients and an opportunity for the manufacturing industry to differentiate in order to attain a competitive edge. Data collected is used in improving the quality of the products. In addition, connected services play a vital role in creating higher margins and revenue streams.

2. Consumer-Driven Manufacturing

Based on research, consumer demands shift with a change in technology. This habit makes it difficult for the manufacturing industry to satisfy the in-demand needs of the clients.

In most cases, customers expect prompt services. Therefore, manufacturing companies in 2022 will opt for ways of improving customer services. This means that a firm should be more flexible and agile to support the current system.

Therefore, firms should avoid the traditional business models. A firm will optimize the profit through integrating high-tech technology, such as the internet of things(IoT), data analytics, and artificial intelligence (AI), into the existing software and systems.

In addition, manufacturers should implement key strategies, such as asset location monitoring, digital quality control, and automated replenishment. These strategies are crucial in increasing operational efficiency.

3. Increased Automation

Automation plays an essential role in eliminating error-prone and time-consuming processes. This will help manufacturing companies to compensate for employee shortages. Technologies such as smart machines, AI, and machine learning will improve consistency, decision making, and quality, and uptime.

4. Predictive Maintenance

According to certain studies, predictive maintenance technology plays a vital role in automating the manufacturing process. This is achieved through predicting problems that might occur in the manufacturing process, particularly in the long term.

The main advantages of predictive maintenance are greater cost efficiencies and reduced downtime. Based on research, predictive maintenance technology will achieve digital transformation and increase customer demand.

5. Shifting From B2B to B2C

Numerous manufacturing companies have shifted from B2B to B2C due to various factors, such as brand control, MSRP pricing, higher margins, etc. To sustain this move, the manufacturing industry should improve operations that aim at supporting e-commerce and customer experience.

Therefore, manufacturers should focus on online customer service, digital marketing, rapid delivery, and secure payments.

Conclusion

Manufacturing trends in 2022 will improve the overall growth of the economy. Above-listed are the key trends that you should expect this year. The right strategies will improve the manufacturing processes, thus enhancing the rate of production.